UTS DEVELOPED A ROBOT IMPROVING SAFETY FOR BRIDGE INSPECTORS

The Sydney Harbour Bridge has 7.2 kilometres of hidden tunnels and confined spaces. (ABC News: Nicole Chettle)

University of Technology Sydney (UTS) engineers and Roads and Maritime Services (RMS) have spent five years focusing on the robot which makes it easier and safer for inspectors.

Bridge Inspector Laurent Matkovic entering a 30-centimetre-wide opening in tunnels on the archway of the Sydney Harbour Bridge. (ABC News: Nicole Chettle).

“It’s better to send a machine into a confined space than myself, because if something happened to me I would be blocked inside,” bridge inspector Laurent Matkovic said.

Indeed, the air quality inside the arches is considered a big issue. Also, emergency rescue is another big problem. That’s why people would prefer to use robots to do the dangerous jobs.

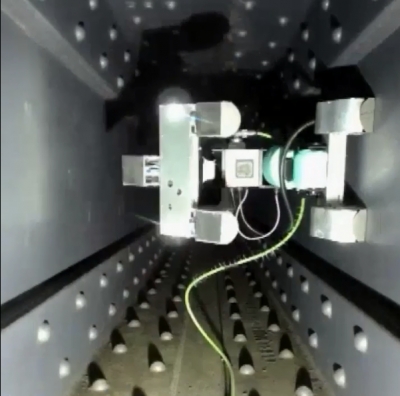

SIX SECONDS SHOWS HOW THE ROBOT WORKS:

The robot applies a three-dimensional sensor to create a map of the dark tunnels, and then moves through the spaces with its magnetic feet. Engineers above can use the camera to assess any damage for it sends back real-time information to them.

A UTS engineer near the summit of the Sydney Harbour Bridge inspects the live map being created by the robot in the tunnel below. (ABC News: Nicole Chettle)

The engineers revealed that the upcoming feature of this robot, which is planned to be ready in three years, is that it can repaint the section while vaporizing rust using laser beams. Moreover, the robot is expected to have a vacuum to remove waste, and be active enough to complete the job without the involvement of workers in the arches.

Peter Ward, one of the UTS engineers proudly said that this world-first improvement could have essential applications overseas.

NGOC TRAM

(Summarized from ABC News and UTS News)